Guide to Finding Injection Molding Partners in China

Well, the major meeting has just concluded. your new project has the green light, the timeline is aggressive, and funding is, to put it mildly, limited. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Naturally, you agree. On paper, it’s logical. The potential savings can be massive. Yet your thoughts are already spinning. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

But here’s the catch. Sourcing China injection molding doesn’t have to be a gamble. It’s a project, just like any other. And like any project, it succeeds or fails based on the process you follow. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Ignore the nightmare anecdotes. Here’s a practical playbook to nail it.

Initial Step: Prepare Your Information

Before searching suppliers or opening Alibaba, nail down your requirements. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. A vague RFQ is like telling a contractor to bid on “a house.” You’ll get wildly varied quotes that are useless.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This package is your project’s foundation.

What should you include?

Start with your 3D design files. These are non-negotiable. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the authoritative CAD geometry.

However, 3D alone won’t cut it. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Call out smooth surfaces or precision hole sizes in big, bold notation.

Then specify the material. Avoid generic terms like “Plastic.” Don’t even just say “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. What’s the reason? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

Your supplier might propose substitutes, but you must set the baseline.

Finally, include the business details. State your EAU. They need clarity: is it 1,000 total shots or a million units per annum? Cavity count, tooling cost, and per-unit pricing depend on volume.

The Great Supplier Hunt

With your RFQ perfected, now, who do you send it to? Online sourcing is global but crowded. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Treat them as initial research tools, not final solutions. Narrow your pool to about a dozen promising firms.

However, don’t end your search there. Consider using a sourcing agent. Yes, they take a cut. But a reputable agent brings pre-screened factories. They are your person on the ground, navigating the language and cultural barriers. As a newcomer, this offers priceless security. Think of it as insurance for your project timeline.

Another classic method? Trade shows. With budget permitting, Chinaplas or similar shows are invaluable. Nothing beats a face-to-face conversation. Inspect prototypes, interview engineers, and sense their capabilities. And don’t forget the oldest trick in the book: referrals. Consult trusted colleagues. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, the quotes will start trickling in. You’ll see ridiculously low offers and steep quotes. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It’s a bit of an art and a science.

Begin with responsiveness. Do they respond quickly and clearly? Do they communicate effectively in English? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” This is a massive green flag. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Ask for a list of their equipment. Seek samples or case studies of comparable projects. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Then comes the audit. Skipping this is a mistake. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They’ll send a local inspector to the factory for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s the best few hundred dollars you will ever spend on your project.

Transforming CAD into Real Parts

After picking your vendor, you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Then comes the real action.

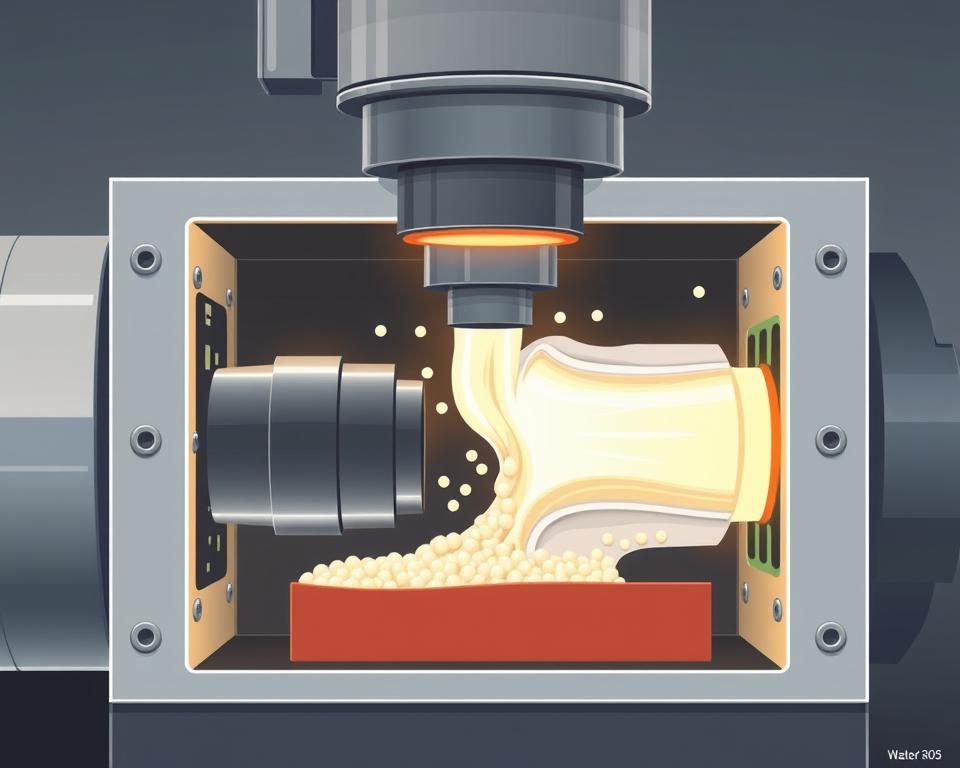

Initially, expect a DFM report. DFM means Design for Manufacturability. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It becomes a joint effort. You work with their engineers to refine the design for optimal production.

When you greenlight the DFM, they machine the mold. In a few weeks, you’ll see “T1 samples are on the way.” These are your initial mold shots. They are your moment of truth.

Expect T1s to need tweaks. That’s standard process. You’ll find minor defects, off-spec dimensions, or finish issues. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. This process might take a couple of rounds. Build buffer time for sample iterations.

Eventually, you will receive a part that is perfect. Dimensions, finish, and performance all check out. This becomes the “golden sample.” You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Getting that golden sample feels like the end, but it isn’t. Next up: mass manufacturing. How do you maintain consistency for part 10,000?

Implement a robust QC plan. This often involves a pre-shipment inspection. Again, you can hire a third-party service. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This step saves you from a container of rejects.

Finally, think about logistics. Know your shipping terms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It hinges on strong supplier relations. View them as allies, not vendors. Transparent dialogue, respect, and process discipline win. Certainly, it’s complex. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’ve got this.